The fastest in China? NONONO, we the fastest in the world.

As we all know, the digital printing technique is the fastest printing technique, of which the ink jet printing is the best. There are 2 types of ink jet printing technique: thermal foaming technology and piezoelectric technology. Memjet is developed from multiple semiconductor chips based on thermal foaming technology, the newly designed ink channel technology can accurately print and the print head with a relatively wide width (the width of the print head is 222.8 mm). Due to the super high cost performance, the Memjet printing technology stands out from many numerous enterprises which is also the first advanced technic to change printhead from fixed assets to consumables and greatly reduce the operation cost of machines.

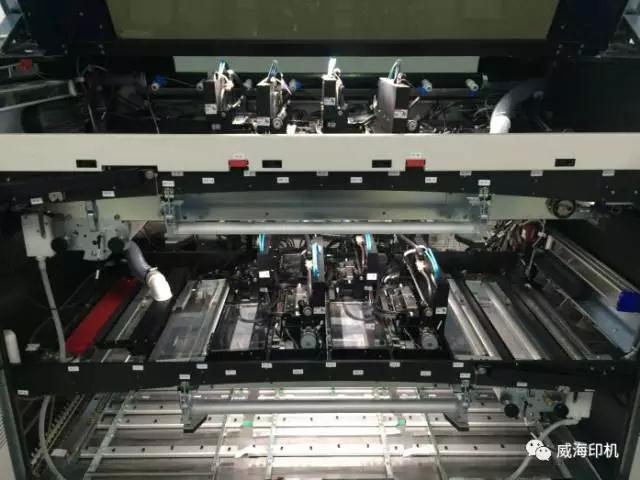

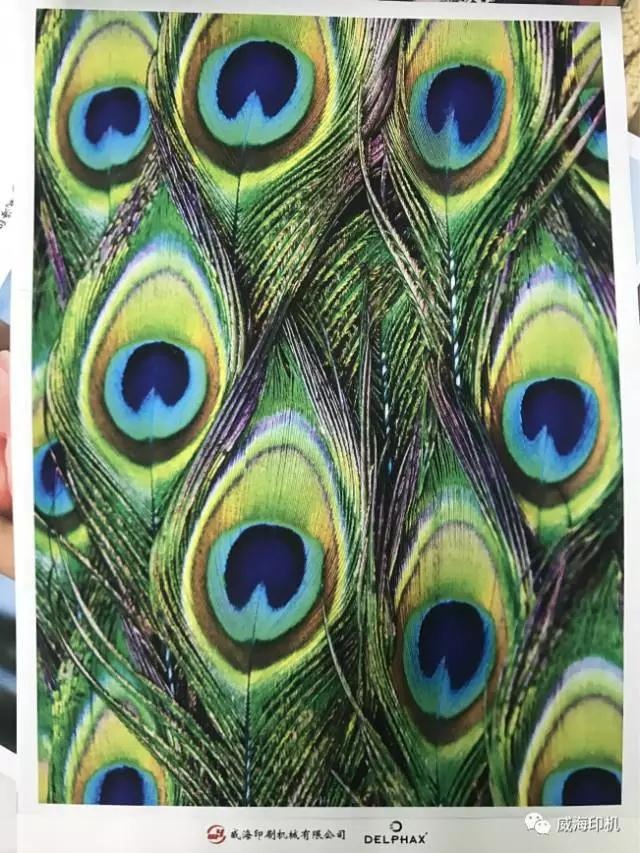

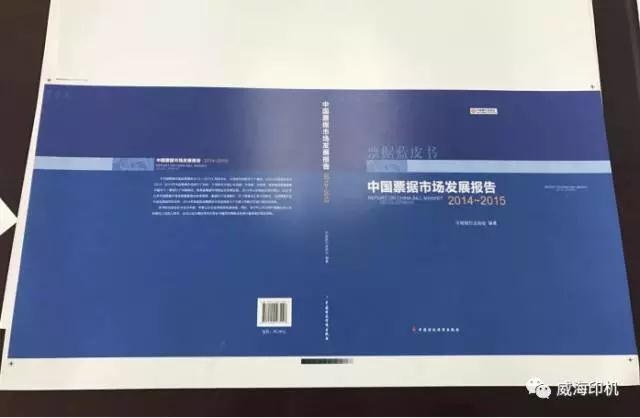

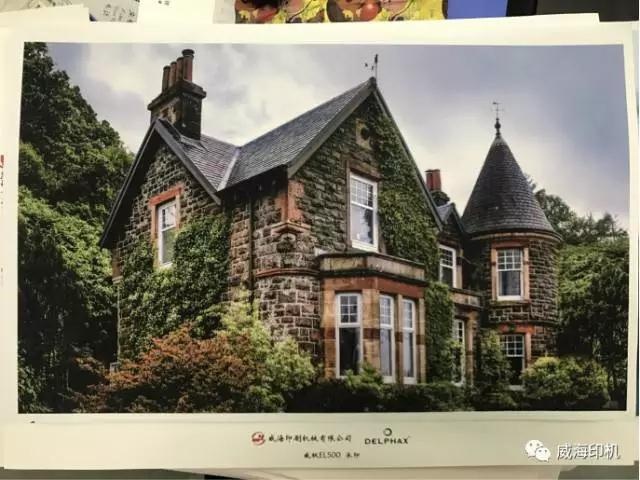

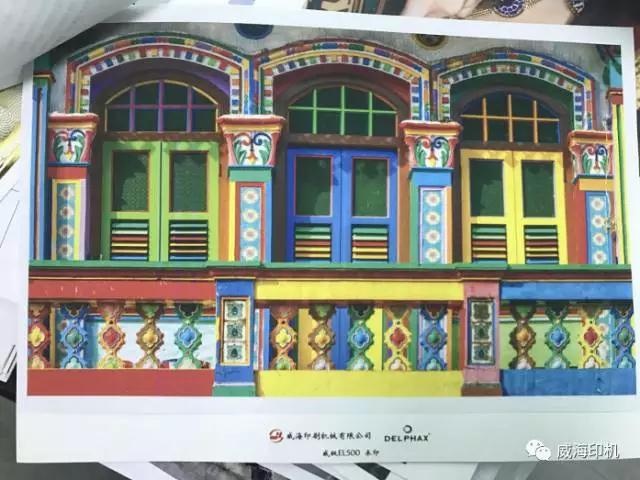

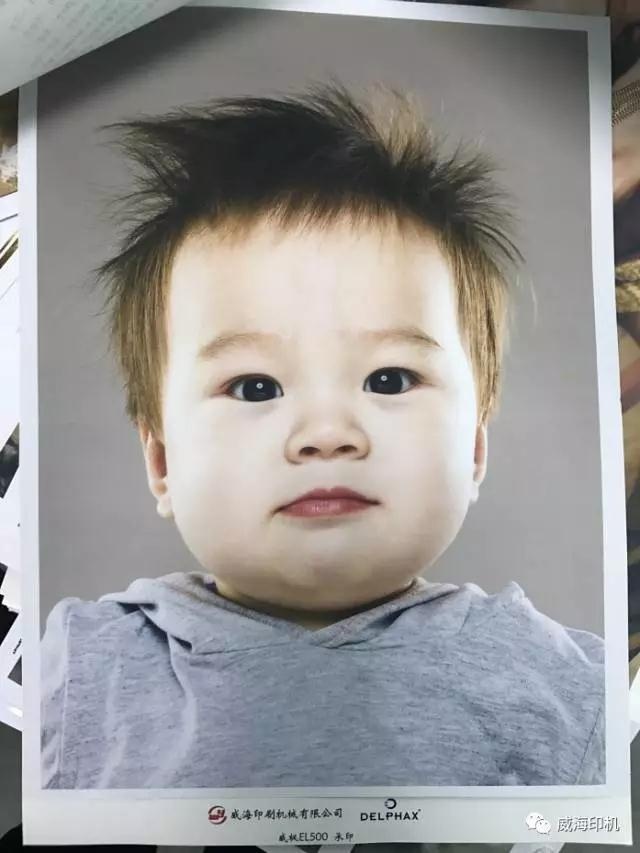

Today we are going to introduce the Weifeng elan500 high speed digital ink jet printer, it is the best treasure of our company. The printer is designed with the advanced Memjet printing technique, and developed by Weihai Prinitng Machinery and Delphax Company (Canada), it is currently the fastest sheet fed, duplex printing, full color digital inkjet printer in the world.

Weifeng elan500 high speed digital ink jet printer is integrated with the epoch-making inkjet image printing technology from Memjet Company with the printing resolution of1600DPI, the Delphax Company’s advanced paper path technology, the developedprinting control system and powerful software function. The win-win cooperate of these two companies has brought users a printer of high efficiency, which include the patented paper transmission system for single pass duplex printing, a wide ranged printing stock, and a high speed printing technique of 500 A4 images per minute which is amount to 3725 SRA2(450X640mm) per hour. The Weifeng elan500 printing process is based on the Adobe PDF technology, which is compatible to the customers’ requirement for personalized printing and management process.

Now I will introduce the high speed digital ink jet printer in details.

A: Paper feeding

The paper feeding machine is highly intelligent sheet-fed and with high capacity, no need of compressed air. Roll to sheet-fed cut paper feeding or a third-party solution are optional.

B: Cleaning

The paper feeding module cleaning device can wipe out the dust and impurities of the paper.

C: Paper transport

The innovated and patented curvilinear paper transport mode can realize double-sided printing in a single pass.

D: Ink

The CMYK ink box with a high capacity of 4Lwhich is convenient to install and replace and the printing task is not necessary to stop.

E: UPE

Interchangeable universal print engine with 5 ink channels for each printhead, 70400 nozzles which can spouts out over 700 million drops of 1.1 pl ink per second. 500 A4 images can be printed every minute.

F: Static electricity

With the SST patented static electricity paper walking transmission system, the duplex printing can be done with a single path and guarantee the duplex printing registration.

G: Monitor

The advanced automatic register control system can monitor the printing quality and guarantee the registration and image quality.

H: Cleaning

The automatic cleaning device of electrostatic transmission system can ensure paper path smoothly and the high print quality.

I: RIP

The RIP architecture design is extensible and upgradable which can meet faster and heavier printing requirements.

J: Interface

The interface is very convenient for users and it is complied with the ergonomics design, enabling powerful software function including media databasewhich can save printing time .

K: Sampling

The verification output tray can print and collect the test page, printed samples at the same time, the sampling inspection for printing quality can be done at the same time of the printing process.

L: Stacker

The high capacity stacker that holds uo to 5000 sheets at 75gsm, optional shingle conveyor or other integrated finishing solutions.

Next let’s check the technical specificationsAdvantages analysis

1. The perfect combination of high speed and low cost: Take the A4 paper colorful print as an example, the printer can duplex print 500 A4 images in 1 minute with only a few cents. The low cost and high print quality made it really outstanding.

2. Individual personalization, printing on demand for both short run and long run can be easily finished: For traditional printing industry, the initial start-up cost is relativelyhigher, the cost could only be lowered downwhen the printing volume goes up. But as the market’s demand for personalized printing, small amount and short run printing is getting bigger and bigger, lots of printing houses with traditional printers have to give up such orders considering the cost and price factors. Weifeng elan500 high speed digital ink jet printer can solve this problem perfectly with digital printing, no need of initial platemaking cost, one book or even one sheetof flyer can be printed easily, thus the start-up cost is saved, and the printer can meet the customer’s personalized requirements easily.

3. Environmental protection. We’re living in a time of environmental protection in which the environmental issue has attracted more and more attention meanwhile the policy continues to tighten up. More and more printing companies are beginning to consider purchasing digital printers. The consumptive material for Weifeng elan500 high speed digital ink jet printer are just printhead and ink which are pollution-free and environmental friendly, it can benefit the country and the people and the posterity.It is your best choice.